Latest News

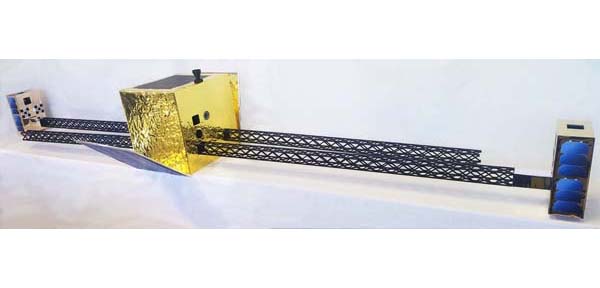

Photo by Made in Space

Made In Space is developing an in-space manufacturing system to enable precision long-baseline interferometry missions. This technology, known as Optimast-SCI (Structurally Connected Interferometer) equips an ESPA-class small satellite with the company’s extended structure manufacturing technology. It enables the deployment of a 20-meter optical boom interferometer with modular internal optics bench developed with Lowell Observatory.

Optimast-SCI is a mission application developed from the company’s Archinaut program and leverages manufacturing capabilities that have been validated on orbit and in a thermal vacuum environment. Optimast SCI’s manufacturing system — which recently reached a critical testing milestone qualifying it for a spaceflight — is a self-contained, scalable machine capable of producing microgravity-optimized structures on-orbit.

According to the release, Optimast-SCI’s in-space configuration can resolve faint objects at less than 5 milliarcsecond resolving power and enable new high resolution, space-based missions in astrophysics, planetary science, Earth remote sensing, and space situational awareness, all with no atmospheric distortion. Eliminating the turbulent distorting effects of the atmosphere by operating from space will allow the observatory to examine objects of interest for as much as 10,000 times longer than a terrestrial observatory.

Get the latest Via Satellite news!

Subscribe Now