Latest News

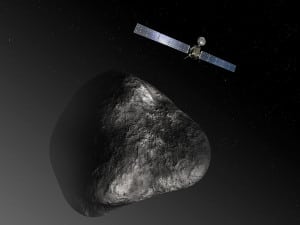

[Via Satellite 12-17-2014] The European Space Agency (ESA) has made a test — originally created for its Rosetta comet-chaser mission — readily available to all European space missions. The test helps ensure propellant tanks will not crack up when subject to aggressive chemical corrosion.

“Stress corrosion cracking has been termed the ‘sleeping monster’ of the aerospace industry, first highlighted in the 1950s with cases of aircraft landing gear unexpectedly cracking overnight,” said Giancarlo Bussu at ESA’s Materials Technology section.

The multicell frame design, built under ESA contact by Germany’s space agency DLR, allows many samples to be tested at once, providing a large amount of data for statistical analysis. It is used for hazardous chemical tests at DLR’s facility in Lampoldshausen and non-toxic testing at ESA’s European Space Research and Technology Center (ESTEC), in Noordwijk, the Netherlands.

“Since then it has been employed during the development of ESA’s Vega launcher, as well as for validating a greener alternative to propulsion simulants for ground-based vibration testing of satellites,” said Tommaso Ghidini, head of ESA’s Materials Technology section. “Right now, it is being prepared for testing more environmentally friendly space propellants, as well as assessing the effectiveness of chromium free protective coatings.”

Get the latest Via Satellite news!

Subscribe Now