Latest News

[Via Satellite 12-23-13] After decades of uncontested use, hydrazine is being challenged by a new upcoming fuel in the spacecraft propulsion market. Together with Aerojet Rocketdyne, NASA and the U.S. Air Force, Ball Aerospace’s Green Propellant Infusion Mission (GPIM) is using 15 years of work to create a competitive satellite propellant called Hydroxyl Ammonium Nitrate (HAN) fuel/oxidizer blend, or AF-M315E.

This new propellant was developed mostly because of environmental concerns regarding hydrazine, pushing the need for a cleaner fuel. NASA’s GPIM mission, scheduled to launch as a secondary payload in 2015 onboard SpaceX’s Falcon Heavy rocket, will be the first space-based demonstration of the fuel.

“Historically its all been monomethylhydrazine (MMH or hydrazine) and nitrogen tetroxide (N2O4) fuels for which a lot of the material characterizations, compatibility work and handling were developed in the late 1960s and early 1970s,” Chris McLean, GPIM principle investigator at Ball Aerospace, told Via Satellite. “We haven’t had a real paradigm shift in space storable propellant since then.”

Hydrazine, being an extremely dangerous chemical, has been listed by the European Chemicals Agency on its Candidate List of Substances of Very High Concern for Authorization. In 2008 the U.S. Navy destroyed an irreparable U.S. spy satellite (U.S 193) based on concerns that its hydrazine fuel storage would survive atmospheric reentry. Concern over the safety of hydrazine has been longstanding, but the reason AF-M315E has taken so long to produce is primarily due to difficulty making use of its operational temperature and catalyst agent.

“The reason it took 15 years to get this fuel accepted was it’s a very high temperature fuel,” explained McLean. “The high temperature is in a sense, an indicator of the performance, because of the amount of energy coming out of it. The AF-M315E is a catalytically decomposing fluid that goes into a catalytic engine, and the temperatures are quite in excess of anything we’ve done before with this type of catalytic reaction. About two years ago Aerojet Rocketdyne in Redmond Washington had a breakthrough with the catalyst technology that allowed the catalyst to survive the temperatures of this propellant. Until they had gone through with that breakthrough, the most time we had seen out of these engines was on the order of seconds before all of the catalyst would wash out. Now we’re looking at comparable life if not better to that of hydrazine technology.”

The new “green” fuel is powerful enough to operate in place of hydrazine at a much safer level.

“[It has] very low toxicity,” said Mclean. “The lethal dose 50 (LD50 metric) is what we use. If you have a scale from one to 10, 10 would be hydrazine, gasoline is around four to five and AF-M315E is around 1.5. It ranks up there with caffeine and drinking too much water.”

Besides the safety and environmental benefits, AF-M315E provides cost-savings benefits as well. “Studies from the Air Force and NASA Goddard indicate there are cost savings to be had of around half a million dollars per launch, with the training and the suits and all the provisions that go around handling the other types of fuel compared to this,” McLean added.

The GPIM will test out two different types of thrusters, both of which see extensive commercial use. Four 1-newton thrusters will test the satellite attitude control, while a single 22-newton thruster will serve as the primary divert engine for large maneuvers. “We want to demonstrate this technology and make it ready for the marketplace so the next user can say ‘hey this does have flight heritage, I can consider this,’” said McLean. “One of the big hurdles is if something hasn’t flown people are reluctant to take the risk of flying and demonstrating a new technology. So the goal of this GPIM infusion mission is to go through those things.”

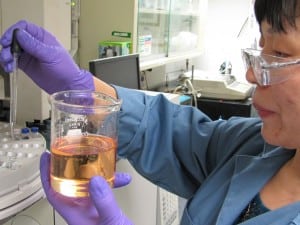

Aerojet Rocketdyne mechanical test technician, sets up the thruster for flow testing in preparation for the 22N firing test. Photo: Aerojet Rocketdyne

The mission makes use of the Ball Configurable Platform (BCP) 100 spacecraft bus to implement AF-M315E. Satellites that make use of the green fuel will have to be designed specifically to do so, which may take some time, but McLean believes it will prove to be a cost-effective decision. “When your look at a mature bus that has a hydrazine system, the odds are the rebuild of the next system wouldn’t employ this, but some of our studies show that when you employ AF-M315E, you can step down a launch vehicle for some LEO type missions,” said McLean. “There’s $20-30 million off your launch price tag right there.”

Still, primary interest is expected to start with public sector uses until the fuel has enough flight heritage to imbue confidence. “Where it comes in first probably NASA then DoD and then probably commercial,” said McLean. “Right now it’s really proprietary and competitive, but there are a handful of requests coming in right now for quotes once the system is available, not only with U.S. NASA, commercial and defense customers requesting when they can get this technology, but also the Europeans are requesting to take a look at our technology as well.”

Stay connected and get ahead with the leading source of industry intel!

Subscribe Now