Latest News

[Via Satellite 04-15-2015] Small satellite launch services provider Rocket Lab has created an engine for its Electron rocket that can be manufactured in three days time. The recently unveiled 4,600 lbf Rutherford engine is primarily produced via additive manufacturing, or 3-D printing, to accelerate the rate of production.

The Electron rocket uses nine Rutherford engines to power the first stage, and one slightly modified Rutherford engine for the second stage. The single second stage engine differs by having a greater expansion valve. Rocket Lab’s desired launch cadence is to achieve at least one liftoff per week. To reach this pace, the company needed to design and produce an engine that could be rapidly manufactured.

“The advantage with additive manufacturing is we can make changes very quickly and the development cycle is very fast; but when it comes to a production standpoint, within three days we have all of the components printed necessary to produce a whole engine. Quality control is exceptional, and it is a cost-effective way to produce these engines in large numbers, which is really critical for our program,” Peter Beck, CEO of Rocket Lab, told Via Satellite.

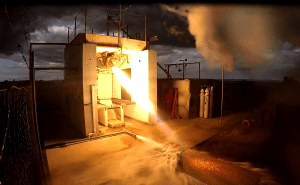

Beck added that Rocket Lab has been conducting hot-fire tests of the Rutherford engine for about a year and a half. The company aims to test the engine every three days on average, he said. All primary parts of the oxygen/hydrocarbon engine are 3-D printed. Rocket Lab also incorporated an electric turbo-pumping system on the engine. The Rutherford engine powers its turbo-pumps using high-performance brushless DC electric motors, and lithium polymer batteries in lieu of gas generators. Beck said this streamlines the design even further, erasing much of the complexity often associated with rocket engines.

“The advantage of electrical turbo-pumping is you decouple the thermodynamic problems immediately, and you turn all the complexity into software, which is infinitely tweak-able, so it really simplifies the system,” he explained. Rocket Lab decided to hone in its Research and Development (R&D) work on creating the battery-powered turbo-pump because it is typically among the most costly and complicated parts of a rocket, according to Beck. Using lithium polymer batteries, the Rutherford engine’s two turbo-pumps produce more than 50 horsepower each. With electric motors to turn the pumps, the Rutherford engine has no gas generator cycles and no turbine.

“We have infinite control over the speed of the pumps so we can do propellant optimization much, much better. We can control the lead legs on startup and shutdown, which is easier with software — we don’t have to have bypass valves and other components,” he said.

Rocket Lab also announced its payload integration method that allows customers to integrate satellites onto the rocket themselves should they desire. The Electron rocket’s upper stage can disconnect payload integration from the main booster assembly. According to the company, integration with the main booster takes just hours to complete.

“That enables us to have multiple payloads at the launch site ready to go and hopefully streamline the integration process as well,” added Beck.

By the end of 2015, Rocket Lab plans to conduct the Electron’s first test flight, leading up to commercial operations in 2016. The company already has more than 30 customers lined up to use the launch system once it is ready. Beck said the Electron launch vehicle has engine-out capability of at least one Rutherford off the pad. The use of nine engines provides redundancy for the launch vehicle. Beck said the number of engines that could be lost without derailing the mission depends on the type of mission and intended orbit. The carbon-composite rocket can loft 100kg payloads to a 500-kilometer sun-synchronous orbit for $4.9 million.

Electron’s launch site is based in New Zealand in order to accommodate the frequency of launches Rocket Lab plans to conduct. The company is based in Los Angeles, Calif.

Get the latest Via Satellite news!

Subscribe Now