Latest News

The environment in which your portable or mobile satellite system is shipped and deployed is characterized by conditions such as temperature, humidity, shock, vibration and air quality. As a first step, you should verify that the components that you plan to use have specifications that meet or exceed these environmental conditions.

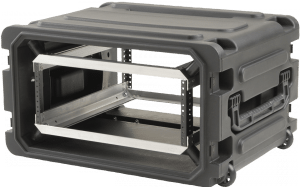

When transporting electronic communication components like satellite modems, automatic antenna controllers and routers, it is necessary to have the proper packaging and environmental considerations in place to reduce the effects that shock, vibration, dust or extreme temperatures can have on the equipment during transportation and use. All electrical components should be securely rack-mounted in a standard 19-inch equipment rack. This can be a fixed, vehicle-mounted rack or a portable, ruggedized rack case for flyaway systems.

For communications hardware that is rack-mounted inside a vehicle, the indoor equipment is pretty well protected from extreme temperatures and dust, but is still subject to damage caused by shock or vibration. Flyaway systems need to have the electronic components protected from shock and vibration, as well as air quality and ambient temperatures.

What is Vibration and Why Does it Matter?

Vibration is defined as motion generated by any mass or force acting on that mass. When dampening technology is not employed, vibration can cause serious damage that can affect or even destroy your equipment. The more delicate parts are used in a piece of equipment’s design, the more hazardous vibration can be to it. There are several different ways to isolate vibration and provide vibration control so that damage is minimized.

Vibration is defined as motion generated by any mass or force acting on that mass. When dampening technology is not employed, vibration can cause serious damage that can affect or even destroy your equipment. The more delicate parts are used in a piece of equipment’s design, the more hazardous vibration can be to it. There are several different ways to isolate vibration and provide vibration control so that damage is minimized.

Vibration suppression is the practice of using a damping, isolation or cancellation solution to reduce or eliminate vibrations that would otherwise affect the useful life of a system component. Damping is a common approach to vibration suppression; it dissipates some of the vibration energy by transforming it to heat. Isolation is often an effective means of vibration suppression when there is a limited path for transmission from a vibrating structure to a sensitive component. Vibration isolation is a technique of isolating an object, such as a piece of equipment, from the source of the damaging vibrations.

If the equipment is permanently installed in an on-board vehicle-mounted equipment rack, the rack should be mounted to the vehicle using suitable vibration dampeners to isolate the rack and its contents from vibrations and shocks during vehicle travel.

Vibration dampeners for on-board equipment racks can be a spring type, wire rope isolator type, vibration pad, rubber shock mounts or pneumatic isolation type. In most vehicles, interior space is fairly limited, so if the on-board vehicle mounted equipment rack is installed in an enclosed compartment, it will need to have adequate space around it for airflow, as well as a ventilation fan system that keeps the equipment well below its maximum operating temperature.

Flyaway Systems

Most mobile and portable satellite systems are designed for the antennae themselves to be outside in hostile environments, but many systems also include indoor, or “below decks” equipment like modems, controllers and routers that must be protected. All equipment of this type should be rack-mounted into a ruggedized rack case that has suitable vibration and shock resistance engineered in.

Most mobile and portable satellite systems are designed for the antennae themselves to be outside in hostile environments, but many systems also include indoor, or “below decks” equipment like modems, controllers and routers that must be protected. All equipment of this type should be rack-mounted into a ruggedized rack case that has suitable vibration and shock resistance engineered in.

Rack case manufacturers like SKB, Pelican, Gator and Zarges all offer rack cases in various sizes, both with and without shock and vibration protection and isolation built in. Always avoid the less expensive portable rack cases that have the rack hard-mounted to the inside of the case. With flyaway satellite antenna cases, every jolt and jar that the case suffers could be transmitted directly to your electronics unless there is sufficient vibration and shock protection built in. Always be sure to select a portable electronics case with a rack that is shock-mounted.

A shock is a sudden and violent blow, impact or collision. This is less likely to happen to equipment that is in an on-board vehicle-mounted equipment rack inside of a mobile command post, but it can happen with something as simple as hitting a pothole in the road if the equipment rack has no shock protection.

A proper shock-mounted equipment rack case will have an internal frame that is mounted on adjustable shock absorbers on all eight corners of the rack itself, controlling the effects of shock on all three axes.

During shipping by commercial carrier, shocks can easily occur during shipping and transportation where the equipment is likely to be dropped, or even have something dropped onto it. A jolt, which would have no effect on most shipments, can be very hazardous to sensitive communications equipment.

Always transport sensitive equipment yourself whenever possible. Every time you turn your equipment over to FedEx or another freight carrier, you are definitely putting your equipment at risk. Freight company employees do not exercise the same care and caution that the owner of the equipment would.

Rack Mounting the Equipment

Most satellite and networking gear will have permanent or attachable “ears” on each side at the front of the chassis for installation into the rack. While this type of mounting is normally sturdy enough to support the weight of the equipment, when the equipment is in a vehicle bouncing down a rough road, or mounted in a portable case that accidently tumbles off the back of a freight truck, the mounting ears can and do break off from the rest of the equipment chassis and allow the component to fall to the bottom of the case or rack. You definitely don’t want to deploy your system once it arrives on site and find that your modem, controller or router came apart and fell out of the rack during transit. For any rack mounted devices that are particularly heavy that have a longer form factor that makes it sit deeply into the rack, or for any rack shelf that contains heavy equipment, it is always best to use a sturdy rear rack support to take the strain off of the faceplate. Many manufacturers include a rear support in their rack mount kits, and these should always be used if provided. If not provided, you should consider fabricating one yourself.

Operational Environment

If the flyaway equipment rack case is to be used outdoors in an area with excessive dust or blowing sand, there is also a need for an air ventilation and filtration system.

Enterprise-grade routers and satellite controllers are equipped with small ventilation fans that are constantly drawing air into the device for cooling. If the cooling fan pulls in air that is contaminated with dirt and dust particles, it creates a permanent layer of dust across everything inside of the device. This layer of dust acts as an insulator, preventing proper heat dissipation from the circuit boards and components. For operations in any environment where your electronics are exposed to the weather, they should be housed inside a sealed National Electronics Manufacturers Association (NEMA) rated enclosure that is equipped with adequate heating or cooling capabilities. Depending on the ambient temperatures where the satellite system will be deployed, this will be accomplished with either a filtered ventilation system or an air conditioning system. In colder environments, a heater may also be required to keep the equipment from freezing. In addition to ensuring that the ambient temperature of your equipment rack is within the specifications for all of the system components, it is vital that you provide adequate cooling clearances around the equipment so that the required air flow is achieved. Once the equipment arrives at the deployment location, be sure to not set the “indoor” electronics rack case directly onto the ground to prevent dirt and water intrusion.

Power Quality and Reliability

The electrical power that you provide to your portable satellite system should be free of any spikes and noise that could degrade performance, reduce operating lifetime and/or cause damage and failure to your electronic equipment. Your equipment must also be connected to an appropriate ground either through the power cord or the chassis grounding screw on the rear of the chassis. You should always use a surge protector if power spikes are a possibility and/or a power conditioner to improve the quality of noisy power. Additionally, you should consider using an Uninterrupted Power Supply (UPS) if your satellite system receives power from an unreliable source like an on-scene generator. Generators provide very unstable, “dirty” power, which can affect the performance and behavior of your equipment. There are several different types of UPS systems; be sure to select one that conditions the power to your electronics, rather than just provides “stand-by power” in case there is an interruption of AC power.

Stocking Spare Components

If you determine that a component in your portable satellite system has failed, you can significantly reduce the downtime of your system by stocking spare components where they can be quickly available to the location where the system is deployed. Stocking a replacement for every component in your system can be expensive, but it can save the day in a critical situation.

If you will follow all of these steps and make sure that your mobile and portable electronics are treated with tender, loving care, you will be much less likely to suffer unexpected equipment failures.

Kirk Williams is the director of sales for Mobil Satellite Technologies. He has more than 15 years of experience in the design and delivery of mobile and portable satellite communications solutions for government and commercial users.

Get the latest Via Satellite news!

Subscribe Now