Latest News

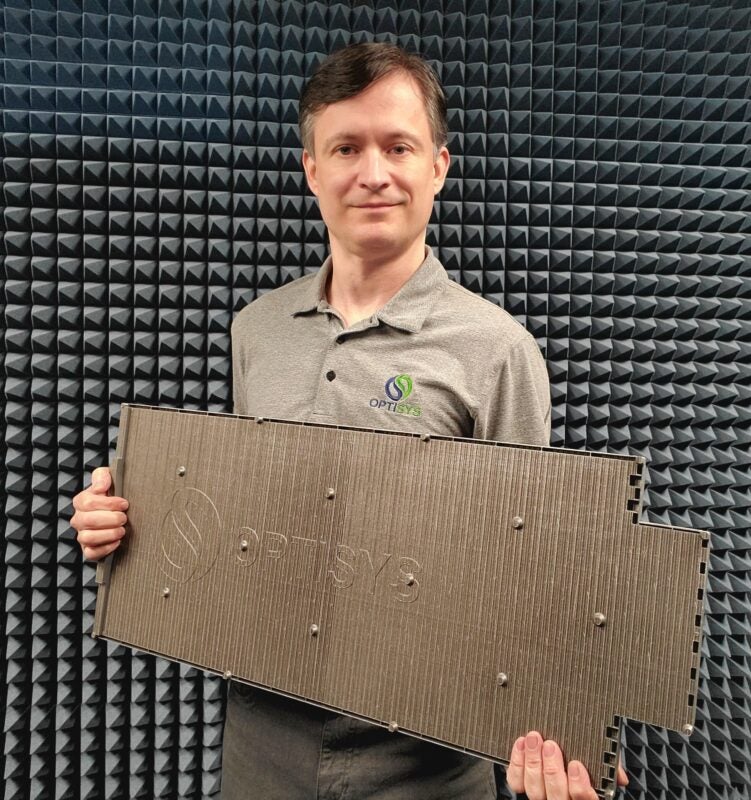

Optisys CEO Janos Opra holds the world’s largest monolithic 3D printed metal antenna. Photo: Optisys

Optisys has recently completed development and production of an antenna that it says is the world’s largest 3D printed antenna. The all metal antenna is a single print, with the design and manufacture of a 0.75 m long flat panel slotted antenna. It was printed in metal as one continuous piece using Direct Metal Laser-Sintering (DMLS) equipment.

The company said this milestone, announced in August, means that the ultra-large tile can form the basis for a larger array, made up of these building blocks, and can be used for applications already covered by Optisys technology, like sea, ground, aerospace, and satellite applications.

“We have been able to produce any size antenna or radar array, using tiling, for a while now,” said Michael Hollenbeck, CTO of Optisys. “However this development brings a new level of cost effectiveness and we have demonstrated our scalability to truly groundbreaking sizes.”

CEO Janos Opra said in a news release that producing this antenna using traditional manufacturing solutions would have required tens or hundreds of parts from multiple vendors. Before this development, Optisys would have printed the antenna in two or three parts, a savings from traditional manufacture, but still two or three levels of overhead.

“We have further reduced this by now only requiring one print and this has greatly reduced the recurring cost for our customers,” Opra said. “This new capability is especially applicable for marine, ground and satellite antennas, which are all normally very big due to the distance their signal has to travel. Now these systems can enjoy better performance and light weight, at a much lower cost than traditional antenna technologies.”

Stay connected and get ahead with the leading source of industry intel!

Subscribe Now